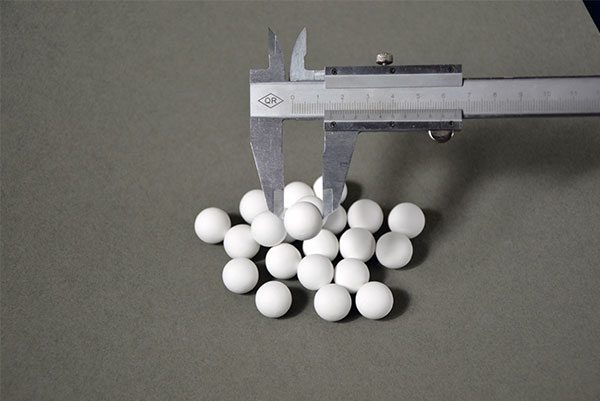

The product is mainly made of ultrafine alumina powder, which is processed through advanced molding technology and high-temperature tunnel kiln firing. Widely used in industries such as petroleum and chemical as tower packing balls and catalyst carriers, it serves as a bottom filling material for hydrogenation refining units, catalytic reforming units, isomerization units, demethylation units, etc. in petrochemical plants, chemical fiber plants, alkylbenzene, ethylene plants, natural gas plants, etc. It has the characteristics of high temperature resistance, high pressure resistance, low water absorption, and stable chemical properties. It can withstand corrosion from strong acids, bases, and other organic solvents, and can adapt to different temperature changes.

Ceramic filler balls have the characteristics of high strength, high temperature resistance, high pressure resistance, strong acid and alkali corrosion resistance, and good thermal shock performance. Mainly used in high-temperature, high-pressure, and highly corrosive working environments in the petrochemical industry, it is the most ideal packing material for conversion furnaces, reaction furnaces, and packed towers in the vast petroleum and chemical industry. Ceramic Raschig rings are a type of loose packing material with a height equal to the diameter size. Laxi ring has excellent acid and heat resistance, and can be used in various strong corrosive, high temperature and low temperature environments. The application range of Rasi ring is very wide, and it can be used in drying towers, absorption towers, cooling towers, regeneration towers, etc. in industries such as chemical, metallurgical, gas, oxygen production, etc.

Typical performance indicators

| Product/Project | 70 series | 80 series | 92 series | 95 series | 99 series |

| AL2O3(%) | ≥70 | ≥80 | ≥92 | ≥95 | ≥99 |

| Fe2O3(%) | ≤0.3 | ≤0.3 | ≤0.2 | ≤0.15 | ≤0.1 |

| Bulk Density£¨g/cm3£© | 2.2-2.8 | 2.5-2.8 | ≥3.0 | ≥3.2 | 3.3-3.7 |

| Water Absorption Rate£¨%£© | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| Single Compressive Strength φ13mm\(N) |

≥3000 | ≥3500 | ≥5800 | ≥5900 | ≥6000 |

| Impact Resistance Strength | ÓÅÁ¼ | ÓÅÁ¼ | ÓÅÁ¼ | ÓÅÁ¼ | ÓÅÁ¼ |

CONTACT US

CONTACT US